Started my internship with Hatton Marine on monday, the first day i worked i didnt work on a turbo like i thought i was. but painting some pipes.

i have some pictures of it here as well. the second day i worked on a john deere turbo, sand blasting the casing and such, taking the measurements for the bearings and shaft

Wednesday, December 12, 2012

Monday, December 3, 2012

Wrapping up Cat3516

Myself and Brennin have been hard at work putting the cylinder of the Cat 3516 back together, first was the liner giving us trouble for some reason, Jeff told us to use a neighboring liner because the ring on ours was cracked and broken off from some one else before us re installing it improperly. Then the piston was a bit easier but we had a hard time getting the connecting rod connected to the crank but we where able to do it and its all good. now just to put the injector and rocker arms back in and finishing it up.

Friday i played a little with flaring tools and all i could get was a single flare. every time i tryed a double flare, i wound up with a single flare or one that was off center.

More practice today and tomorrow on that.

Cant wait to start my internship with Hatton marine on the 10th.

Friday i played a little with flaring tools and all i could get was a single flare. every time i tryed a double flare, i wound up with a single flare or one that was off center.

More practice today and tomorrow on that.

Cant wait to start my internship with Hatton marine on the 10th.

Friday, November 16, 2012

Cummins IXS

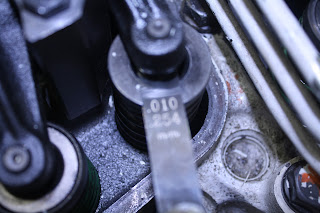

Took the valve cover off and adjusted the valves on the #4 cylinder with Brennin surprisingly the tolerances for that engine where greater than the cummins Bseries that i worked on earlier. where the valves in the B series had to be .010 of an inch plus or minis .001 inch where the ISX could be anywhere between .014 to .020 of an inch.

Finding fault codes on the ISX was a little tricky because it wouldn't talk to the Modis scan tool but we had the laptop with Cumins Insite loaded on it and got several.

the one i chose was Fault Code #2367

Reason. Engine Brake actuator driver 2 circuit voltage above normal or shorted to a high source.

Open circuit or high voltage detected at the engine Brake solenoid #2 signal circuit

Effect.

Engine brakes on cylinders #2 and #3 can be on all the time OR can NOT be activated .

Finding fault codes on the ISX was a little tricky because it wouldn't talk to the Modis scan tool but we had the laptop with Cumins Insite loaded on it and got several.

the one i chose was Fault Code #2367

Reason. Engine Brake actuator driver 2 circuit voltage above normal or shorted to a high source.

Open circuit or high voltage detected at the engine Brake solenoid #2 signal circuit

Effect.

Engine brakes on cylinders #2 and #3 can be on all the time OR can NOT be activated .

Thursday, November 8, 2012

day 33 -37

Day 33

1. Cooling, The answer i got from the document Jeff had us read was that the larger the radiator the cooler you can make the engine. you dont want to make an engine run too cool and you dont want it to run to hot, so you have to have the right size.

2. Detonation. When the fuel begins to burn, it will provide power. (duh) But if detonation happens too soon or to late, it will have an advers effect on your power if it happens to late, and can harm your engien if it happens to soon (pinging)

3. Contamination. Besides the recomended matenence intervals, could an oil change be determened?

By how often the engine runs. how long it runs and its duty cycle. most off shore applications and in boats, its commen that regardless how much the boat goes out that the owners will have the oil changed once a year.

4. Combustion air flow requirments. finishing the statement "Combstion airflow requirements will vary depending on the specific engine model and rateing. spicific air flow data for caterpillar engines is given in both..." Volumetric and mass flow. at staderd reffernce conditions.

Day 34

1.The FCA is the Fuel Control Assembly and it regulates the fuel to the injectors.

2. High Preasure Fuel Warning

3. There are 2 Intake heaters for the Dodge 3500.

4. Vehical throws an Open code for all 6 injectors. meaning that more than likely the harness got torn off or disconected some how. the chance of all six going out at once and needing new injectors is slim. another possobility is the cam shaft position sensor is bad but did not show on this truck so that is still good.but if it did have a code then that could be why the truck is not starting.

5. Making the horn blow and wipers work with the scan tool is called "Bi-Differencal control"

Day 35

1. Scanning the Freightliner for codes came up with a barmetric preasure code that was shorted high.

2.(pic next) seeing the humps on the scope then seeing the longer one let me know that the longer signal was TDC for cylender #1

Day37

1. the 9 functions of oil. Lube, preasure wear control. cleaning, protection, cooloing, sealing, shock dampening, hydrolic action.

2.6 oil contaminits. Combustion biproduct, acid varnish, abrasives, fuel, coolent, soot, and enviermental contaminnts.

3. the 9 sets of data that must be included in oil analysis

Engine modle and Sn#

Miles/Hours of oil use

Miles/Hours since new or rebuild

Oil Used

Date Sample was colected

Engine Application

Amount of oil added since previous oil change

Any recent engine matenince

Analysis of new oil

4. The two methods to take an oil sample are, to use a small vacuum pump and draw a sample from the dipstick, or take some as its draining from the sump at an oil change.

5. ? Odd wording Jeff

6. I learned that the diffrent types of contamination wil lead to diffrent failers and exesive wear on certen parts depending on what type of contamination you have in your oil.

7. EC

The signifigence to "The 11th Hour of the 11th Day of the 11th Month"

Is when most major hostilitys ended during WW1 on the 11th hour of the 11th day of the 11th month with the German singing of The Armistice

1. Cooling, The answer i got from the document Jeff had us read was that the larger the radiator the cooler you can make the engine. you dont want to make an engine run too cool and you dont want it to run to hot, so you have to have the right size.

2. Detonation. When the fuel begins to burn, it will provide power. (duh) But if detonation happens too soon or to late, it will have an advers effect on your power if it happens to late, and can harm your engien if it happens to soon (pinging)

3. Contamination. Besides the recomended matenence intervals, could an oil change be determened?

By how often the engine runs. how long it runs and its duty cycle. most off shore applications and in boats, its commen that regardless how much the boat goes out that the owners will have the oil changed once a year.

4. Combustion air flow requirments. finishing the statement "Combstion airflow requirements will vary depending on the specific engine model and rateing. spicific air flow data for caterpillar engines is given in both..." Volumetric and mass flow. at staderd reffernce conditions.

Day 34

1.The FCA is the Fuel Control Assembly and it regulates the fuel to the injectors.

2. High Preasure Fuel Warning

WARNING:

|

HIGH-PRESSURE FUEL LINES DELIVER DIESEL FUEL UNDER EXTREME PRESSURE FROM THE INJECTION PUMP TO THE FUEL INJECTORS. THIS MAY BE AS HIGH AS 23,200 PSI (1600 BAR). USE EXTREME CAUTION WHEN INSPECTING FOR HIGH-PRESSURE FUEL LEAKS. FUEL UNDER THIS AMOUNT OF PRESSURE CAN PENETRATE SKIN CAUSING PERSONAL INJURY OR DEATH. INSPECT FOR HIGH-PRESSURE FUEL LEAKS WITH A SHEET OF CARDBOARD. WEAR SAFETY GOGGLES AND ADEQUATE PROTECTIVE CLOTHING WHEN SERVICING FUEL SYSTEM

|

3. There are 2 Intake heaters for the Dodge 3500.

4. Vehical throws an Open code for all 6 injectors. meaning that more than likely the harness got torn off or disconected some how. the chance of all six going out at once and needing new injectors is slim. another possobility is the cam shaft position sensor is bad but did not show on this truck so that is still good.but if it did have a code then that could be why the truck is not starting.

5. Making the horn blow and wipers work with the scan tool is called "Bi-Differencal control"

Day 35

1. Scanning the Freightliner for codes came up with a barmetric preasure code that was shorted high.

2.(pic next) seeing the humps on the scope then seeing the longer one let me know that the longer signal was TDC for cylender #1

Day37

1. the 9 functions of oil. Lube, preasure wear control. cleaning, protection, cooloing, sealing, shock dampening, hydrolic action.

2.6 oil contaminits. Combustion biproduct, acid varnish, abrasives, fuel, coolent, soot, and enviermental contaminnts.

3. the 9 sets of data that must be included in oil analysis

Engine modle and Sn#

Miles/Hours of oil use

Miles/Hours since new or rebuild

Oil Used

Date Sample was colected

Engine Application

Amount of oil added since previous oil change

Any recent engine matenince

Analysis of new oil

4. The two methods to take an oil sample are, to use a small vacuum pump and draw a sample from the dipstick, or take some as its draining from the sump at an oil change.

5. ? Odd wording Jeff

6. I learned that the diffrent types of contamination wil lead to diffrent failers and exesive wear on certen parts depending on what type of contamination you have in your oil.

7. EC

The signifigence to "The 11th Hour of the 11th Day of the 11th Month"

Is when most major hostilitys ended during WW1 on the 11th hour of the 11th day of the 11th month with the German singing of The Armistice

Saturday, November 3, 2012

International MaxForce

Over the week myself and Brennin where using the computer on the International outside.

Seeing the different things that the computer is able to see and tell you was interesting. and using the software to fill out the Hard Start No Start sheet and the performance diagnostics sheet.

one test we had to warm up the coolant in the engine and to do that we did a high idle which for that truck the limit was just after 2600 rpm after that the truck would shake and not like it. then what surprised me was some of the tests from the computer would make the truck do different things on its own.

we hit the run test button and the truck behind us reved up and did its own thing.

Sunday, October 28, 2012

Electronics

A few days ago Jeff handed us each a sensor off of a piece of equipment, and i happened to get a differential pressure sensor with a high and low side.

i was able to hook up the leads. power ground and a signal lead. hooking my multi meter inline with the signal wire and ground. i was able to get a base reading of around .25 of a volt for ambient air pressure.

Blowing into the highside i was able to get it up to 4.1 volts out of the 5 volt system i was hooked into. and droped down to .015 of a volt on the low side.

i was able to hook up the leads. power ground and a signal lead. hooking my multi meter inline with the signal wire and ground. i was able to get a base reading of around .25 of a volt for ambient air pressure.

Blowing into the highside i was able to get it up to 4.1 volts out of the 5 volt system i was hooked into. and droped down to .015 of a volt on the low side.

Sunday, October 21, 2012

measurements for 5.9 B series Cummins

After taking the engine apart and inspecting we had diffrent tests and measurments to take to make sure the engine was still in good order.

we found that it was in pretty good order, with a few minor things that needed .

--------------------------

Cylinder head deck flatness.

Minimum out of flatness 0.003 inches. and when measured 0.004 inches

Valve depth min 0.039 inches, max 0.060 inches.

Intake 0.044 inches

Exhaust 0.050 inches

Piston pin was round all the way around with 1.5749 inches. and needing to be replaced because it was at the max

the cylinder bore was round and with in limits

other notes we found the oil pump had flakes of metal in it and whernt from the pump itself. cleaned it up and re installed

Seawater pump. rusty but no signs of pitting or leaking seals

rocker lever pedestal #2, 5 and 6

centering opening in the oil channel, mashed up, concluding where metal in oil pump came from.

Thursday, October 18, 2012

Lethal strike Video

Watched the Lethal Strike Video and wow.

Pressurized oil or fluid squirting out (in the case of the movie 3000 psi) will really screw up your day.

If not treated correctly and taken care of immediately after it happens then the results are grim.

Pressurized oil or fluid squirting out (in the case of the movie 3000 psi) will really screw up your day.

If not treated correctly and taken care of immediately after it happens then the results are grim.

Friday, October 5, 2012

Cummins 5.9 B series

Today me and Daniel started to take apart a Cummins 5.9 Marine Diesel.

Started by draining the oil that was still left in the pan and began to take the valve covers off and the front cover to get to the front gear train. once we could see that we could figure out how to get top dead center (TDC) for the first cylinder and measure the valve lash on the rocker arms and valves.

Attached are about 50 pictures of what we have so far.

Started by draining the oil that was still left in the pan and began to take the valve covers off and the front cover to get to the front gear train. once we could see that we could figure out how to get top dead center (TDC) for the first cylinder and measure the valve lash on the rocker arms and valves.

Attached are about 50 pictures of what we have so far.

Subscribe to:

Comments (Atom)