A few days ago Jeff handed us each a sensor off of a piece of equipment, and i happened to get a differential pressure sensor with a high and low side.

i was able to hook up the leads. power ground and a signal lead. hooking my multi meter inline with the signal wire and ground. i was able to get a base reading of around .25 of a volt for ambient air pressure.

Blowing into the highside i was able to get it up to 4.1 volts out of the 5 volt system i was hooked into. and droped down to .015 of a volt on the low side.

Sunday, October 28, 2012

Sunday, October 21, 2012

measurements for 5.9 B series Cummins

After taking the engine apart and inspecting we had diffrent tests and measurments to take to make sure the engine was still in good order.

we found that it was in pretty good order, with a few minor things that needed .

--------------------------

Cylinder head deck flatness.

Minimum out of flatness 0.003 inches. and when measured 0.004 inches

Valve depth min 0.039 inches, max 0.060 inches.

Intake 0.044 inches

Exhaust 0.050 inches

Piston pin was round all the way around with 1.5749 inches. and needing to be replaced because it was at the max

the cylinder bore was round and with in limits

other notes we found the oil pump had flakes of metal in it and whernt from the pump itself. cleaned it up and re installed

Seawater pump. rusty but no signs of pitting or leaking seals

rocker lever pedestal #2, 5 and 6

centering opening in the oil channel, mashed up, concluding where metal in oil pump came from.

Thursday, October 18, 2012

Lethal strike Video

Watched the Lethal Strike Video and wow.

Pressurized oil or fluid squirting out (in the case of the movie 3000 psi) will really screw up your day.

If not treated correctly and taken care of immediately after it happens then the results are grim.

Pressurized oil or fluid squirting out (in the case of the movie 3000 psi) will really screw up your day.

If not treated correctly and taken care of immediately after it happens then the results are grim.

Friday, October 5, 2012

Cummins 5.9 B series

Today me and Daniel started to take apart a Cummins 5.9 Marine Diesel.

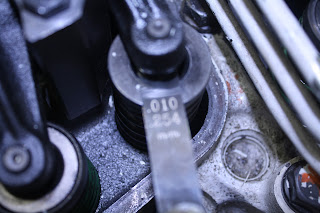

Started by draining the oil that was still left in the pan and began to take the valve covers off and the front cover to get to the front gear train. once we could see that we could figure out how to get top dead center (TDC) for the first cylinder and measure the valve lash on the rocker arms and valves.

Attached are about 50 pictures of what we have so far.

Started by draining the oil that was still left in the pan and began to take the valve covers off and the front cover to get to the front gear train. once we could see that we could figure out how to get top dead center (TDC) for the first cylinder and measure the valve lash on the rocker arms and valves.

Attached are about 50 pictures of what we have so far.

Subscribe to:

Comments (Atom)